Medical Waste Sterilization Systems

Vertisa Environmental Technologies Ltd. is a young and dynamic company which has been formed with individuals who have vast experience in the Medical Waste Sterilization business.

Vertisa develops complete medical waste sterilization related solutions for hospitals, clinics and industrial size medical waste treatment facilities in general.

By utilizing our know-how gained from 20 year experience in the medical waste sterilization field, we provide equipment that is adapted to the specific needs of the industry, that could only be developed by a sterilization expert.

Our company operates under ISO 9001, ISO 14001, OHSAS 18001 quality standards, and our products are produced according to European Union Directives like PED (2014/68/EU), 2006/42/EC, 2014/30/EU and European Union Norms like EN285.

Our brand PROMED is one of the most widely used solutions around the globe for the sterilization and decreasing of volume of waste originating from healthcare facilities.

PROMED is the most innovative model in the field of “medical waste treatment and disposal” serving for more than 150 clients in more than 35 countries around the world. Promed Pre- Shredding and Post- Shredding Sterilization Systems have been designed by our Research and Development department engineers using our vast experience in this field.

Bio Medical – Infectious Waste Sterilization

Medical wastes are among hazardous wastes generated by healthcare institutions like hospitals, clinics, laboratories, health research facilities and their disposal requires special methods prior to land filling. Bio-Medical wastes are divided into infected and non-infected wastes and the infected wastes require treatment. Incineration is one of the oldest methods for treatment of medical wastes, but their usage have faced wide objections due to emission of hazardous gases such as CO2 and CO as well as Carcinogenic gases such as Dioxins and Furans which are generated as a result of incomplete combustion of compositions like PVCs. Autoclave is one the newest methods of medical wastes treatment which works based on wet disinfection.

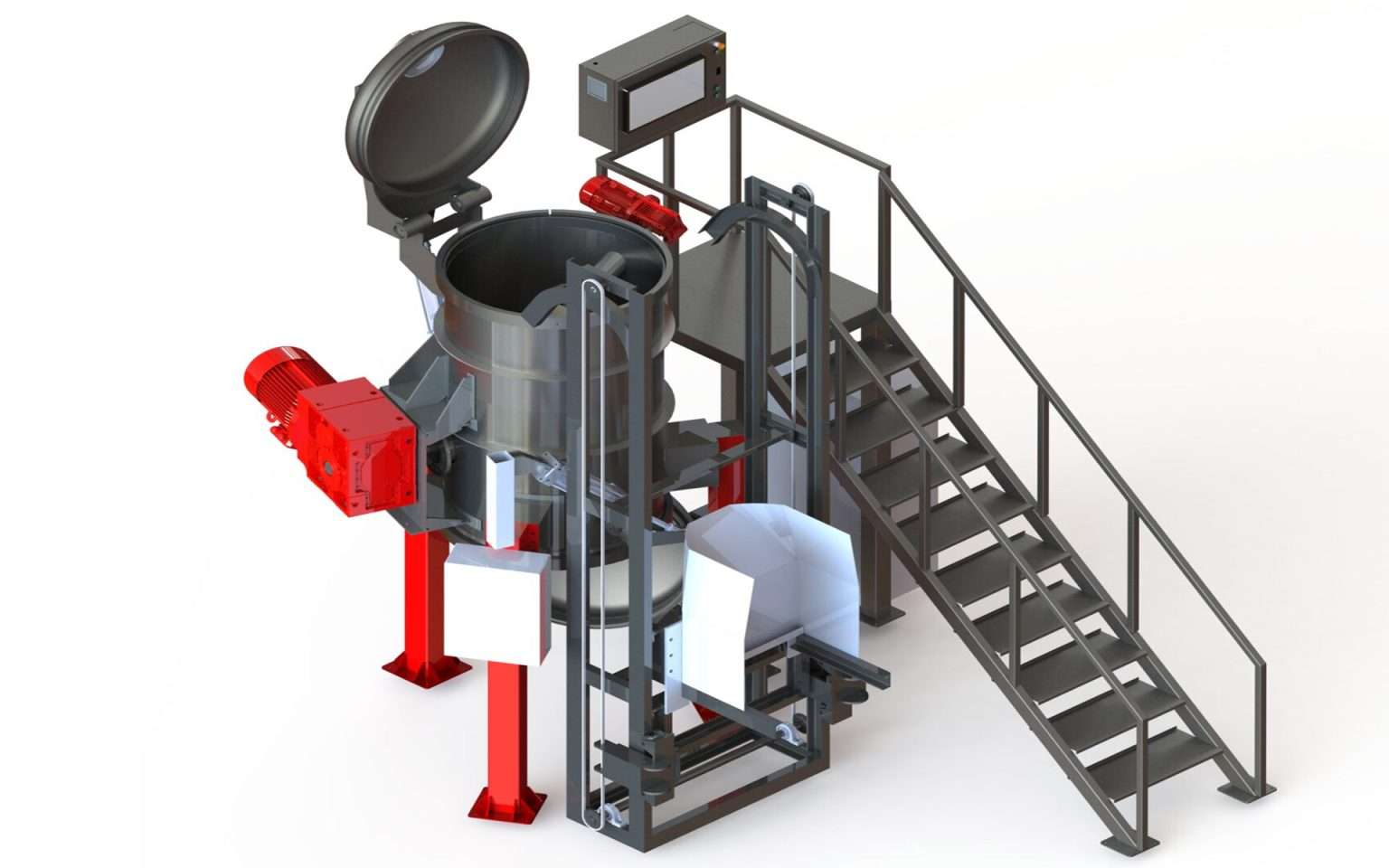

Autoclaves are closed chambers that apply heat, pressure and steam, over a period of time to sterilize medical equipment. For medical waste that will be disposed of, autoclaves are used as heat treatment processing units to destroy microorganisms before disposal in a traditional landfill or further treatment. Autoclaves are a batch process, not a continuous one. Autoclaves are “chemical free” and that appeals to many stakeholders in a complex waste management environment.

Pressure container built of high quality Stainless Steel

Design and production certified by TUV Austria

Produced according to EU Directives PED (2014/68/EU) 2006/42/EC, 2014/30/EU & EU Norms EN285

Sophisticated automation control system with advanced reporting and monitoring software

Online access via internet for supervision and troubleshooting|

Fully automatic operation- no need for any operator intervention

Automatic elevator system for easy loading

No water consumption

Low fuel and electrical consumption for integrated steam boilers equipped with state of the art steam regeneration system.